Your trusted partner for Service, Calibration and Training

SERVICE

Safe Contractor Certified

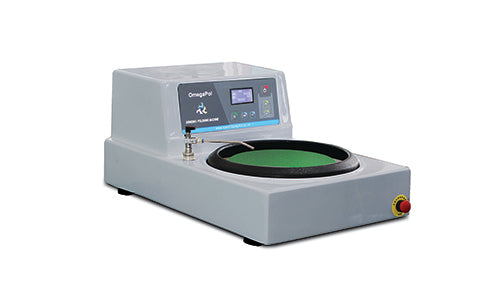

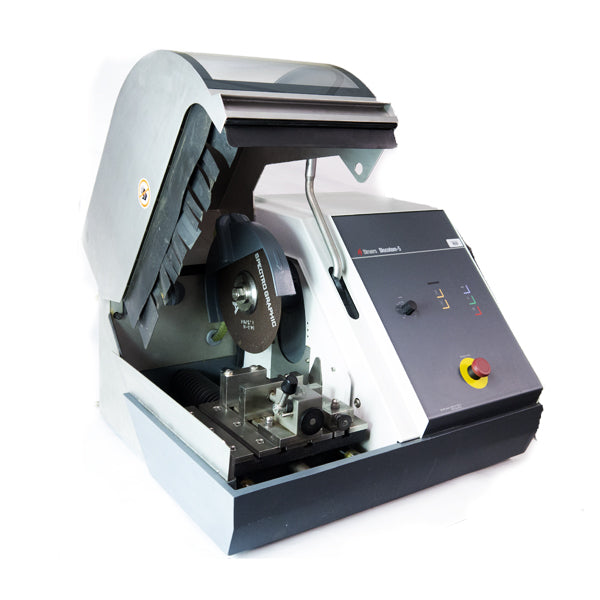

We offer repair, calibration and full routine service for your machines. Our Service Engineers have over 20 years knowledge of working on all brands of metallurgical preparation equipment. For the best satisfaction and machine longevity, we encourage you to use our Service team for all your calibration and maintenance needs. We are committed to providing proper repair and calibrations to maximise the performance of your machines. Not only can we service most metallurgical equipment, we can overhaul and repair too. If you have any questions, contact a member of our Service team 01943 879001

WE SERVICE & REPAIR MOST BRANDS OF MACHINES

TRAINING ON MACHINES

We offer comprehensive on-site machine training specifically tailored for the metallurgy industry. Our expert-led sessions are designed to ensure your team gains hands-on experience with the latest equipment and techniques used in modern metallurgical processes. Whether it’s operating, maintaining, or optimising machines, we provide practical, real-world training that enhances efficiency, safety, and technical skills—all delivered directly at your facility for maximum convenience and impact.

MACHINE SPARE PARTS

PREPARATION ROUTES

CALIBRATION OF HARDNESS TESTERS - UKAS

The calibration process is defined in the standard as follows:

Assessment of the general conditions

Direct testing - UKAS

Indirect testing

Drawing up of the calibration certificates

What is meant by calibration?

Calibration means that a measurement is performed in which the measured object (test specimen or calibration object) is compared with the values of a better and traceable standard according to a documented method. The result of the calibration is expressed with deviation and measurement uncertainty so that the calibration result is also traceable. The calibration is intended to ensure that the hardness tester, which is also relevant for the product quality, produces the “right” results.

What is a direct verification?

A direct verification of the hardness testing machine directly checks all measurement variables used for determining the hardness value.

CONTACT 01943 879001 FOR A QUOTE

WHAT OUR CUSTOMERS SAY

GET A QUOTE NOW